-

FEMALE JIC SWIVEL TO FEMALE PIPE CONNECTOR 6506

Precio habitual A partir de $2.99 USDPrecio habitualPrecio unitario / por -

6502 Male Jic - Female Jic Swivel Elbow 45 Degree

Precio habitual A partir de $12.99 USDPrecio habitualPrecio unitario / por -

2601 Male Jic - Male Jic - Male Pipe Branch Tee

Precio habitual A partir de $3.99 USDPrecio habitualPrecio unitario / por -

6602 Male Jic - Female Jic Swivel - Male Jic Run Tee

Precio habitual A partir de $3.99 USDPrecio habitualPrecio unitario / por -

6504 Male Jic - Female Jic Swivel Extender

Precio habitual A partir de $3.99 USDPrecio habitualPrecio unitario / por -

2501 Male Jic - Male Pipe Elbow 90 Degree

Precio habitual A partir de $1.99 USDPrecio habitualPrecio unitario / por -

2404 Male Jic - Male Pipe Connector

Precio habitual A partir de $4.99 USDPrecio habitualPrecio unitario / por -

2606 Male Jic - Female Pipe - Male Jic Run Tee

Precio habitual A partir de $9.99 USDPrecio habitualPrecio unitario / por -

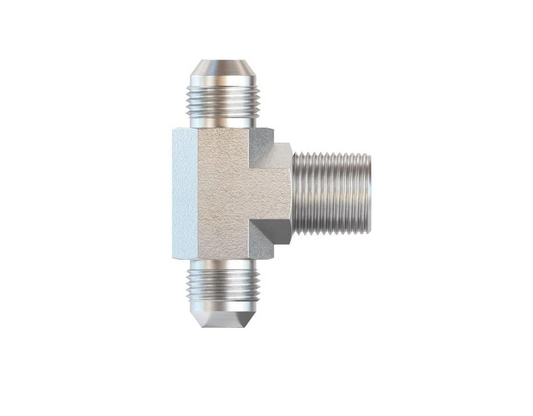

2605 Male Jic - Male Pipe - Male Jic Run Tee

Precio habitual A partir de $3.99 USDPrecio habitualPrecio unitario / por -

2603 Male Jic - Male Jic - Male Jic Union Tee

Precio habitual A partir de $2.99 USDPrecio habitualPrecio unitario / por -

2602 Male Jic - Male Jic - Female Pipe Branch Tee

Precio habitual A partir de $5.99 USDPrecio habitualPrecio unitario / por -

2504 Male Jic - Male Jic Elbow 45 Degree

Precio habitual A partir de $4.99 USDPrecio habitualPrecio unitario / por -

2502 Male Jic - Female Pipe Elbow 90 Degree

Precio habitual A partir de $14.99 USDPrecio habitualPrecio unitario / por -

2405 Male Jic - Female Pipe Connector

Precio habitual A partir de $6.99 USDPrecio habitualPrecio unitario / por -

2403 Male Jic - Male Jic Union

Precio habitual A partir de $4.99 USDPrecio habitualPrecio unitario / por -

6600 Male Jic - Male Jic - Female Jic Swivel Branch Tee

Precio habitual A partir de $3.99 USDPrecio habitualPrecio unitario / por

* Stainless Steel JIC Fittings FAQs

Contenido desplegable

1. What are stainless steel JIC fittings?

Stainless steel JIC (Joint Industry Council) fittings are hydraulic compression fittings made from corrosion-resistant stainless steel alloys. They feature a 37-degree flare seating surface and parallel threads, designed to meet SAE J514 standards for leak-free, high-pressure connections.

2. What are the benefits of using stainless steel JIC fittings?

Stainless steel JIC fittings offer superior corrosion resistance, durability, and robustness compared to other materials like brass or carbon steel. They can withstand extreme temperatures, harsh environments, and high-pressure applications, making them ideal for industrial, automotive, and heavy equipment use.

3. How do stainless steel JIC fittings seal?

JIC fittings create a metal-to-metal seal by establishing contact between the male flared end and the female coned seat. This mechanical connection does not require thread sealants like Teflon tape, ensuring a secure, leak-free joint.

4. What types of stainless steel are used for JIC fittings?

316 stainless steel is a common grade used for JIC fittings, offering excellent corrosion resistance and strength at high temperatures. Other grades like 304 stainless steel may also be used depending on the application requirements.

5. Can stainless steel JIC fittings be used with NPT (National Pipe Thread) configurations?

Yes, stainless steel JIC fittings can be adapted for use with NPT configurations through the use of appropriate NPT adapters or transitions.

6. What are some common applications for stainless steel JIC fittings?

Stainless steel JIC fittings are widely used in hydraulic and fluid power systems, including industrial machinery, construction equipment, agriculture, automotive, and marine applications where corrosion resistance and high-pressure capabilities are required.

7. How do I select the right size stainless steel JIC fitting?

Stainless steel JIC fittings are available in various sizes, typically denoted by dash sizes (e.g., -4, -6, -8) or fraction sizes (e.g., 1/4", 3/8", 1/2"). Consult sizing charts or manufacturer specifications to ensure proper fit and compatibility with your hydraulic system.

8. Can stainless steel JIC fittings be used with O-ring boss or ORB configurations?

Yes, stainless steel JIC fittings can be adapted for use with O-ring boss (ORB) configurations through the use of appropriate adapters or transition fittings.

9. Are stainless steel JIC fittings more expensive than other materials?

Stainless steel JIC fittings are generally more expensive than brass or carbon steel fittings due to the higher cost of stainless steel alloys and their superior corrosion resistance and durability.

10. Where can I find pricing and purchase stainless steel JIC fittings?

At https://www.mrhydraulic.com/ you can find anything you want, in case you need assistance don't hesitate to send us a message sales@hydraulicwarehouse.com